Erqi District, Zhengzhou City, Henan Province

Monday-Sunday:7:00AM - 23:00PM

A number you can call:+86 13164350935

The professional legal department, the rapid after-sales service response and the high standard requirements for each link all come from the continuous exploration and pursuit of the metal material industry of Wanzhi Iron & Steel over the years.

We always provide people a complete solution focused of any business.

Different types of transportation to meet the needs of various customers.

We have more than

years of experience

The predecessor of Wanzhi Group was founded in 2002 in Henan ZidongIron and Steel Center by the founder and chairman of the group, Mr. Wang Huamin.

Wanzhi Steel is a subsidiary of Wanzhi Group's import and export business. It relies on Zhengzhou Wanzhi Materials Co., Ltd., a branch in Henan Province, responsible for the operation of metal materials import and export business. It is also the own trademark and brand of Wanzhi Group.

Learn MoreA variety of product categories

wanzhi

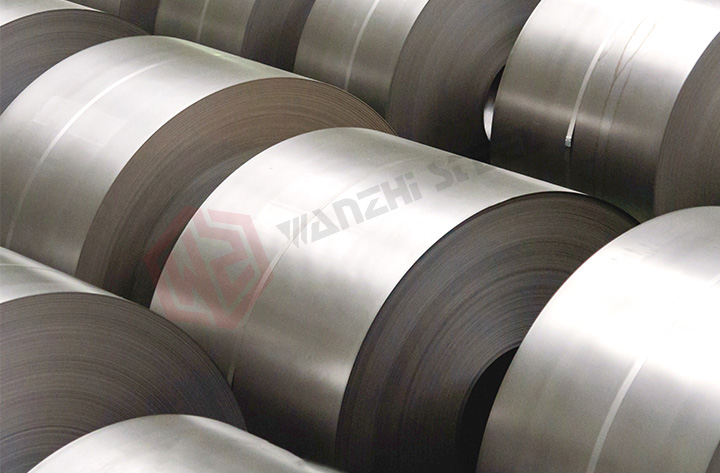

Cold rolled stainless steel refers to cold rolled steel plate, is the steel plate produced by cold rolling.

Read More

wanzhi

Cold rolled stainless steel refers to cold rolled steel plate, is the steel plate produced by cold rolling.

Read More

wanzhi

Cold rolled stainless steel refers to cold rolled steel plate, is the steel plate produced by cold rolling.

Read More

wanzhi

Cold rolled stainless steel refers to cold rolled steel plate, is the steel plate produced by cold rolling.

Read More

wanzhi

Hot - rolled stainless steel steel plate is made by hot - rolled process. Thickness of not more than 3mm for the thin plate, thickness of more than 3mm for the thick plate for the chemical, petroleum, machinery, shipbuilding and other industries manufacturing corrosion resistant parts, containers and equipment.

Read More

wanzhi

Hot - rolled stainless steel steel plate is made by hot - rolled process. Thickness of not more than 3mm for the thin plate, thickness of more than 3mm for the thick plate for the chemical, petroleum, machinery, shipbuilding and other industries manufacturing corrosion resistant parts, containers and equipment.

Read MoreDo You Want To explore more products just click here

We undertake a variety of types of medium-scale engineering projects, focusing on the overall expansion of our business scope and multi-channel parallelism, so far the rapid growth.

Adopt the high quality stainless steel material, do not rust, do not fade, not easy to scratch.

A variety of processing technology, a full range of to meet your needs.

Layers of strict control, unqualified products do not leave the factory customers rest assured.

Craftsmanship casting, carefully polished every detail, to ensure quality.

Widely used in various fields

Widely used in machinery and equipment manufacturing, electronics, electrical appliances, computers, high-tech product parts, etching, auto parts, kitchen supplies, adjusting gaskets, metal stamping spring shrapnel, stainless steel foil used for die and other industries.

Response within 5 minutes before sales, quotation within 1 hour at the fastest, first sample in 3 days at the fastest, conventional supply 2 days shipment.

Online consulting

This article will look at the reasons why galvanized steel is becoming increasingly popular.

No matter what kind of products, the production process is always important, a good production process can make the product become more outstanding and perfect, stainless steel plate is also the case, and in the production and processing of stainless steel plate series there are very many and strict requirements.

Stainless steel plate is a kind of universal and very popular stainless steel material on the market, which has very good rust corrosion resistance, high temperature resistance and good intergranular corrosion resistance. Rust resistance than 200 series of products to be more strengthened, high temperature resistance can also reach 1000-1200 degrees.

It has 9 major metal materials import and export departments, covering more than 90 kinds of metal

materials products throughout the entire industrial chain.